Single-purpose machines

We design and produce single-purpose machines with varying degrees of automation for industrial enterprises and smaller manufacturing or assembly companies.

Thanks to our many years of experience, we design solutions that precisely meet the needs of our customers and are optimized both technically and economically.

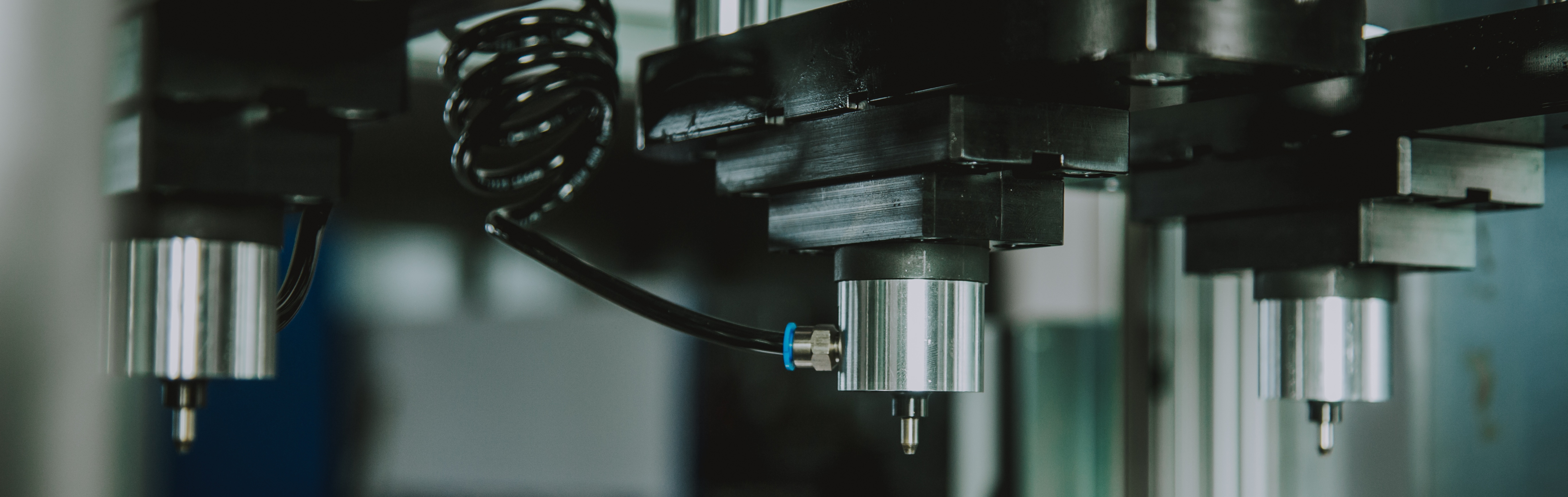

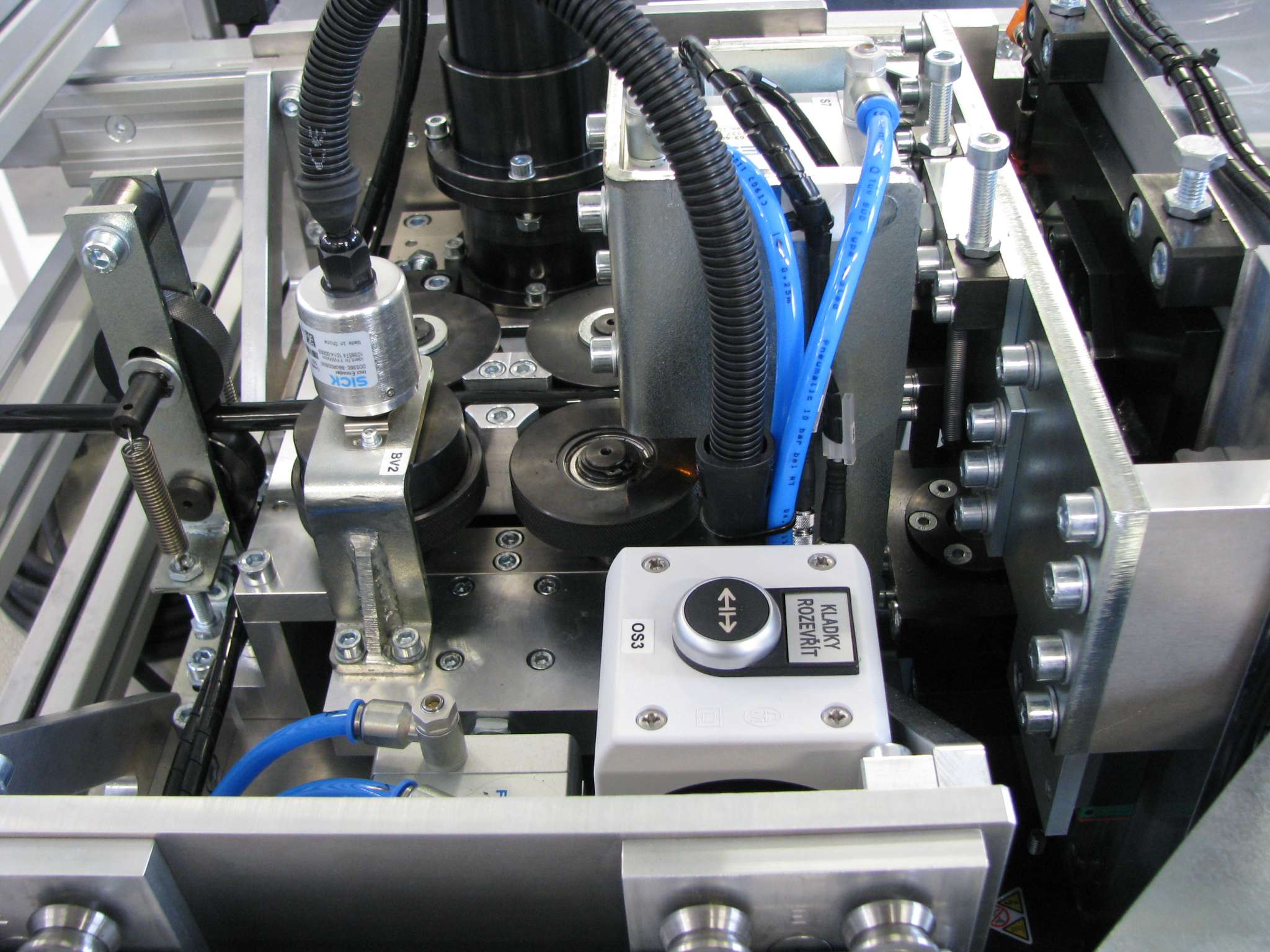

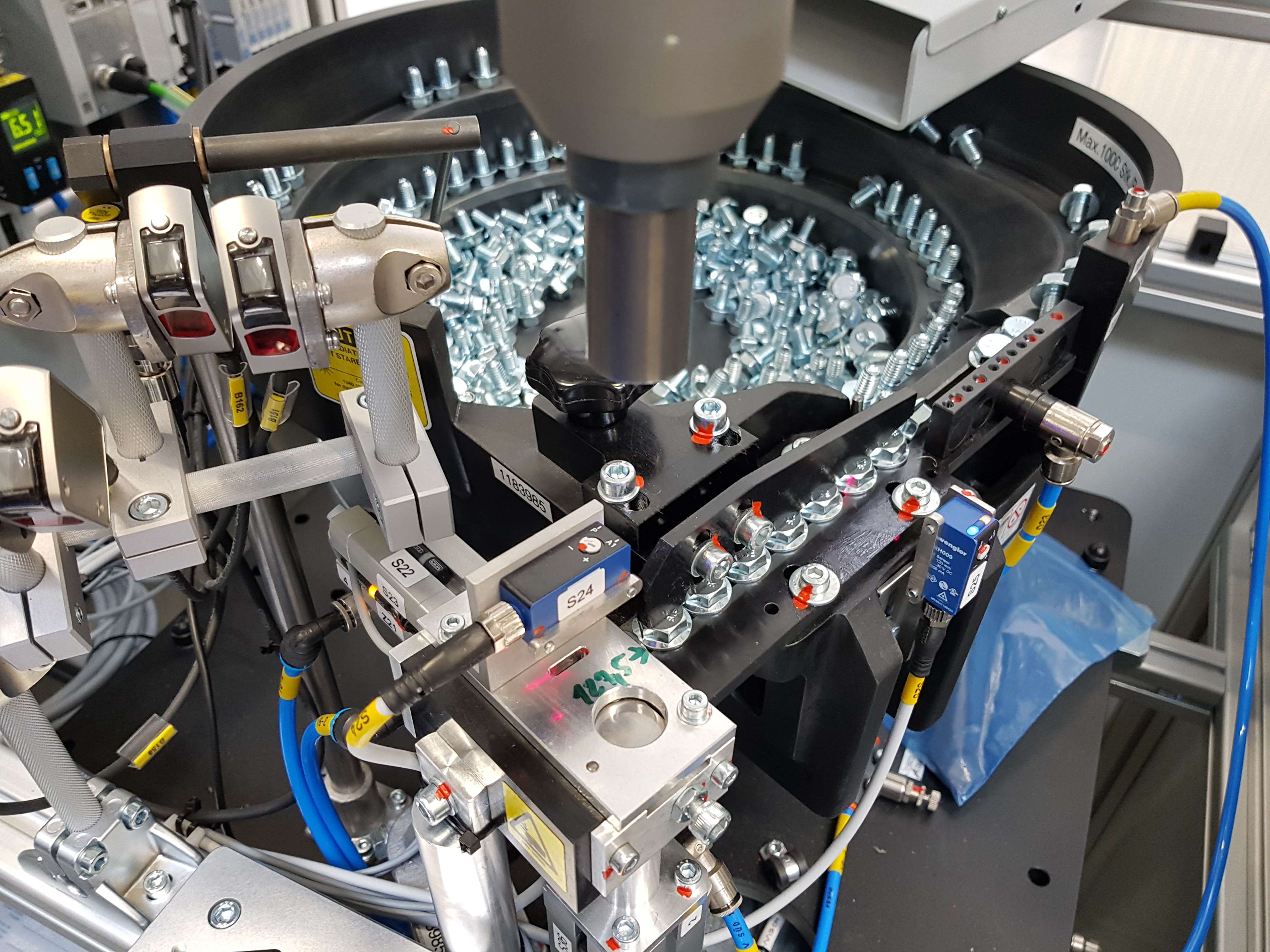

What will your single-purpose machine do? The most commonly fitted technologies:

• Robotic handling

• Testing

• Screwdriving

• Pressing and riveting

• Material dispensing

• Lubricant and adhesive dispensing

• Welding: Ultrasonic, Spinweld, Laserwelding

• Product marking: labels, laser marking, engraving

• Conveyors: pallet, belt, gravity, roller

• QR code lasers, RFID, camera detection

• MES and remote management

Advantages of single-purpose machines:

• Significant increase in production and efficency

• Reduction of scrap rates

• Decrease in labour costs and number of production operators

• Reduction of dependence on the labour market

Manual workplace

For small batch production or for technologically demanding processes where automation is not suitable, we create manual workplaces where the main assembly part is performed by an operator. A customized workplace increases the quality and speed of production, ensures the smoothness of the process and compliance with the correct procedure. We equip the loading bed with POKA YOKE systems for error proofing detection of the input parts.

Semi-automatic workstations

Higher production series and repetitive processes are provided by the semi-automatic workstation, which is a sophisticated combination of automatic elements with manual work of the operator. Thanks to the precise design, testing and implementation of the POKA YOKE system, it guarantees smooth and high-quality production with high capacity and low rejection rates.

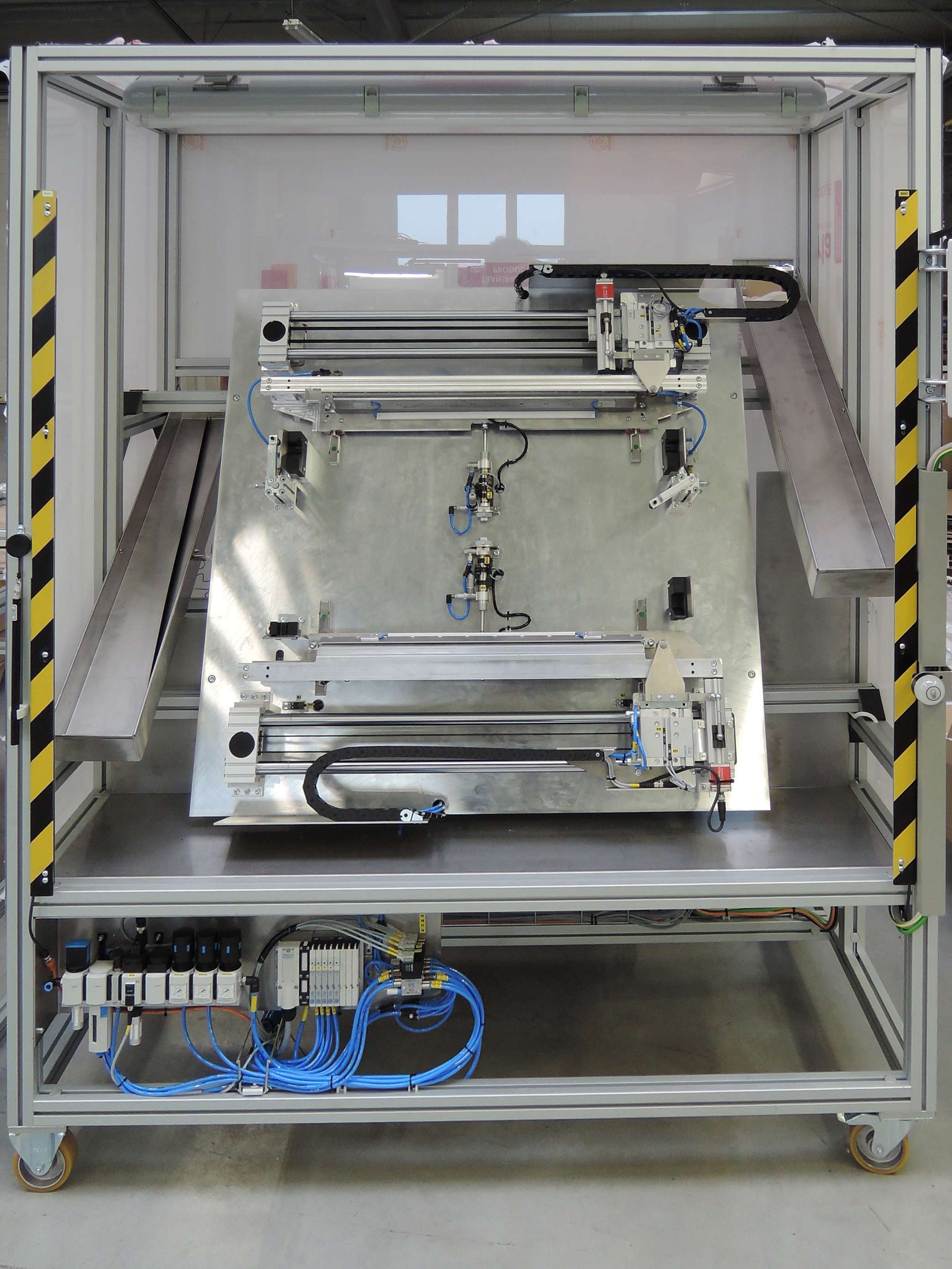

Automatic workstations

In order to achieve high production volumes with minimal need for operators, we design and implement automatic production workstations that serve as a separate production unit or part of the production line. All material and parts handling is automatic. A typical example is the carousel workstation.